High-Pressure Cylinder Test for Airbag Inflation

It is now absolutely necessary to use a professional automotive airbag high-pressure steel cylinder testing machine to conduct the relevant tests for the cylinders in order to ensure their quality and safety during the production process.

Project

The principle of the airbags is that when a car is involved in a collision, compressed steel gas cylinders filled with gas rapidly inflate airbags in the center of the steering wheel and the side of the dashboard to reduce and prevent injuries of the driver and passengers. A high quality automotive airbag system cannot ignore the quality of the air reservoir cylinders, because once a cylinder bursts, the force of the high velocity gas may project cylinder fragments to the surrounding areas as well as people and cause significant injuries. Nations worldwide have currently established standards associated with the manufacturing, quality, and testing of the high-pressure cylinders. Therefore, it is now absolutely necessary to use a professional automotive airbag high-pressure steel cylinder testing machine to conduct the relevant tests for the cylinders in order to ensure their quality and safety during the production process.

Requirements

The various types of the steel cylinders must undergo the relevant cylinder verification tests during the manufacturing process. Among them, the two most important are the fatigue and burst tests.

The fatigue test must be able to conduct continuous tests by automatically adding and reducing pressure by preconfigured amounts.The system must be able to reciord the testing data and calculate the relative pressure and time curves.

System Features

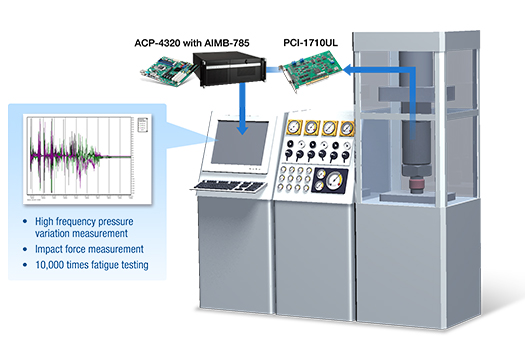

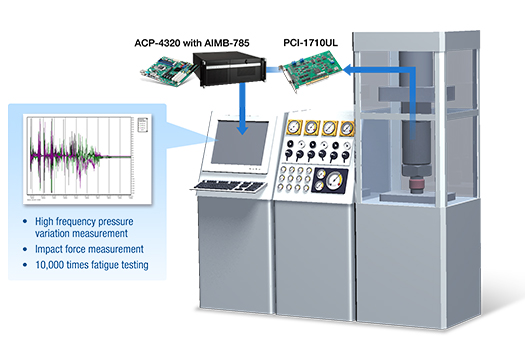

Advantech provides a series of products that can perform high-speed pressure and flow volume measurements as well as equipment control for this application case sample. Advantech?s industrial-grade 4U rackmount IPC ACP-4320 chassis with AIMB-785, the 6th generation Intel® Core? i motherboard is used in combination with the PCI-1710UL to perform rapid data acquisition; instantly display the information collected on the human-machine interface; and begin to perform analyses, recording, report generation, etc. In terms of obtaining accurate pressure data based on customer requirements, the PCI-1710UL equipped by the industrial-grade computer is a high-speed analog input card that can capture the changing pressure signals rapidly and continuously. Its 100Ks/S high-speed sampling rate and 12-bit high resolution can perform rapid data acquisition at the speed 100 times fasterthan that of a PLC. When the test machine performs the pressurization and decompression fatigue test ten-thousand-time for a steel cylinder, the PCI-1710UL has the sampling rate of ten thousand times per second through the machines pressure sensors. This can significantly enhance the sampling rate to capture the changing pressure signals rapidly and continuously, and thereby resolve the customers? PC/PLC system data distortion problems.

The principle of the airbags is that when a car is involved in a collision, compressed steel gas cylinders filled with gas rapidly inflate airbags in the center of the steering wheel and the side of the dashboard to reduce and prevent injuries of the driver and passengers. A high quality automotive airbag system cannot ignore the quality of the air reservoir cylinders, because once a cylinder bursts, the force of the high velocity gas may project cylinder fragments to the surrounding areas as well as people and cause significant injuries. Nations worldwide have currently established standards associated with the manufacturing, quality, and testing of the high-pressure cylinders. Therefore, it is now absolutely necessary to use a professional automotive airbag high-pressure steel cylinder testing machine to conduct the relevant tests for the cylinders in order to ensure their quality and safety during the production process.

Requirements

The various types of the steel cylinders must undergo the relevant cylinder verification tests during the manufacturing process. Among them, the two most important are the fatigue and burst tests.

The fatigue test must be able to conduct continuous tests by automatically adding and reducing pressure by preconfigured amounts.The system must be able to reciord the testing data and calculate the relative pressure and time curves.

System Features

Advantech provides a series of products that can perform high-speed pressure and flow volume measurements as well as equipment control for this application case sample. Advantech?s industrial-grade 4U rackmount IPC ACP-4320 chassis with AIMB-785, the 6th generation Intel® Core? i motherboard is used in combination with the PCI-1710UL to perform rapid data acquisition; instantly display the information collected on the human-machine interface; and begin to perform analyses, recording, report generation, etc. In terms of obtaining accurate pressure data based on customer requirements, the PCI-1710UL equipped by the industrial-grade computer is a high-speed analog input card that can capture the changing pressure signals rapidly and continuously. Its 100Ks/S high-speed sampling rate and 12-bit high resolution can perform rapid data acquisition at the speed 100 times fasterthan that of a PLC. When the test machine performs the pressurization and decompression fatigue test ten-thousand-time for a steel cylinder, the PCI-1710UL has the sampling rate of ten thousand times per second through the machines pressure sensors. This can significantly enhance the sampling rate to capture the changing pressure signals rapidly and continuously, and thereby resolve the customers? PC/PLC system data distortion problems.